Cold filter point is one of the important indexes to measure the low temperature performance of oil products. In the process of transportation, storage and use of diesel oil, when the external temperature is low, the paraffin wax in the diesel oil precipitates, which makes the diesel oil become sticky or even solidified, resulting in the blockage of the filter or nozzle, which leads to the failure of normal fuel supply to the diesel engine. Therefore, it is of great significance to accurately measure the cold filter point of oil products and master its actual low temperature performance for the correct use of diesel oil and to ensure the normal operation of production. In this paper, two batches of No. 0 automotive diesel oil (VI) with the same cold filter point of -10 ℃ from the same factory are used as test oil samples. Through the adjustment of equipment and facilities and operation process in the test process, the factors that may affect the measurement results of cold filter point are analyzed.

1. Brief introduction of cold filter point

The chemical composition of diesel contains a certain amount of long-chain n-alkanes, if the more long-chain n-alkanes, the lower the cold filter point. When the temperature decreases, the wax will gradually precipitate, and the fluidity of diesel oil will become worse and solidify gradually. The cold filter point is the highest temperature at which diesel can flow and it is also an important index of the low temperature performance of diesel oil. As some diesel oil has lost its fluidity before it reaches solidification, there will be the phenomenon that diesel oil cannot be supplied. Therefore, it is of great practical significance to accurately test the cold filter point. In real life, ordinary customers can choose the right grade of diesel according to the temperature of the external weather, which can effectively avoid equipment failure caused by too low temperature and then reduce unnecessary economic losses.

2. The main influencing factors of cold filter point test

In SH/T0248-2019 "determination of Cold filter Point of Diesel Oil and Civil heating Oil", by stuffing the stopper equipped with thermometer and pipette (which has been connected with the filter in advance) into the test cup containing 45mL samples, the thermometer is placed vertically in the test cup, 1.5mm ±0.2 mm away from the bottom of the sample cup, and the filter should also be placed vertically at the bottom of the test cup. By controlling the vacuum pump or pump with sufficient pressure to ensure that the air velocity in the vacuum regulator is 15L/h ±1L/h throughout the test. The above steps are repeated every time that the temperature of the sample is 1℃ lower than the previous one until the precipitation of waxy crystals in the sample is sufficient to stop the flow or decrease the flow rate. When the sample cannot flow through the filter or the 20ml sample to flow through the filter is more than 60s or when the sample cannot completely flow back to the test cup, the highest temperature is the cold filter point of the sample. For two groups of No. 0 automotive diesel oil (VI) with the same cold filter point, adjust the installation conditions of the equipment and facilities of the cold filter point and observe the changes of their cold filter point.

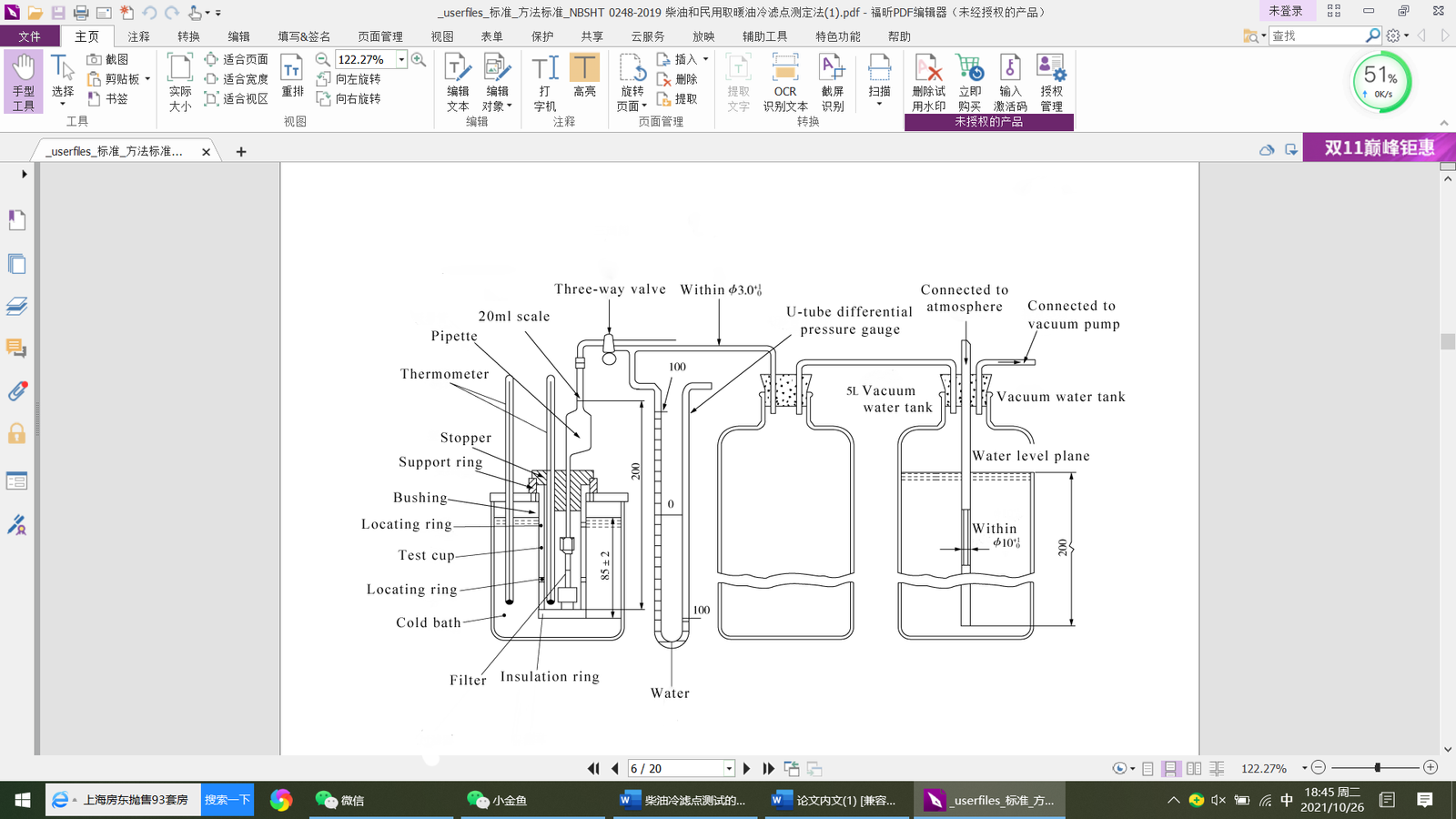

Figure 1. Schematic diagram of instrument assembly

Figure 1 shows the schematic diagram of the cold filter point test instrument assembly. Figure 2 shows the cold filter point tester and the side view of the cold filter

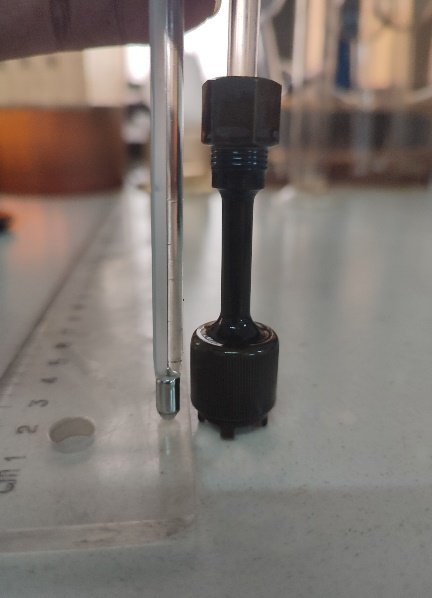

Figure 3. Side view of cold filter point suction device

在此处输入摘要、注释等,你可将文本框放置在文档的任意位置。

Figure 2. Cold filter point tester

point suction device is shown in Figure 3. The thermometer, suction tube and filter device are shown in Figure 4 and the panel of the cold filter point suction device is shown in Figure 5.

2.1 The influence of installing cold filter point equipment on cold filter point

2.1.1 The distance of the filter from the bottom of the test cup

Under the same test conditions, adjust the distance between the filter and the bottom of the test cup, test the cold filter point of the sample and observe the influence of adjusting the position of the filter on the test results of the cold filter point (Figure 4). When the distance between the filter and the bottom of the test cup is in the range of [0, 1.5] (mm) and the step size is 0.5 (mm), the test results of the two groups of cold filter points are shown in Table 1 and Table 2.

Table 1. The influence of the height at which the filter is placed vertically at the bottom of the test cup on the cold filter point (the first group)

|

Distance from the filter to the bottom of the test cup (mm) |

0 |

0.5 |

1 |

1.5 |

|

Test result (℃) |

-10 |

-10 |

-11 |

-11 |

Table 2. The influence of the height at which the filter is placed vertically at the bottom of the test cup on the cold filter point (the second group)

|

Distance from the filter to the bottom of the test cup (mm) |

0 |

0.5 |

1 |

1.5 |

|

Test result (℃) |

-10 |

-10 |

-11 |

-12 |

2.1.2 The distance at which the thermometer is placed at the bottom of the test cup

Under the condition that other test conditions remain unchanged, adjust the installation position of the thermometer in the test cup and observe the influence of the change of the thermometer position on the test results of the cold filter point (Figure 4). When the distance range of the thermometer placed at the bottom of the test cup is [0, 2.0] (mm) and the step size is 0.5 (mm), the test results of the two groups of cold filter points are shown in Table 3 and Table 4.

|

Stopper |

|

U-tube differential pressure gauge |

|

Vacuum regulator |

|

Thermometer |

|

Figure 5. The panel of the cold filter point suction device |

|

Sample cup |

|

Filter |

|

Pipette |

Figure 4. Thermometer, suction tube and filter device

Table 3. The influence of the height of the thermometer on the bottom of the test cup (the first group)

|

The distance the thermometer is placed at the bottom of the test cup (mm) |

0 |

1.0 |

1.5 |

2.0 |

|

Test result (℃) |

-9 |

-9 |

-10 |

-11 |

Table 4. The influence of the height of the thermometer on the bottom of the test cup (the second group)

|

The distance the thermometer is placed at the bottom of the test cup (mm) |

0 |

1.0 |

1.5 |

2.0 |

|

Test result (℃) |

-9 |

-9 |

-10 |

-11 |

2.1.3 Air flow rate of vacuum device

Under other unchanged test conditions, adjust the air velocity of the vacuum device and observe the effect of air velocity on the test results of the cold filter point again (Figure 5). When the range of air velocity is [13,19] (L) and the step size is 2 (L), the test results of cold filter points of the two groups are shown in Table 5 and Table 6.

According to the test results in Table 1, Table 2, Table 3 and Table 4, the crystallization process of the sample in the test cup is slowly precipitated from bottom to top so the distance between the filter and thermometer and the bottom of the test cup will affect the final cold filter point, and the cold filter point will be different with the slight change of position. It can be seen from tables 5 and 6 that the air velocity of the vacuum device also has a certain influence on the determination of the cold filter point.

Table 5. The effect of air velocity on cold filter point (the first group)

|

Air velocity (L/h) |

13 |

15 |

17 |

19 |

|

Test result (℃) |

-10 |

-10 |

-11 |

-12 |

Table 6. The effect of air velocity on cold filter point (the second group)

|

Air velocity (L/h) |

13 |

15 |

17 |

19 |

|

Test result (℃) |

-10 |

-10 |

-11 |

-13 |

2.2 The influence of test operation process on cold filter point

When the sample reaches the specified temperature of 30 ±5 ℃, the sample cup is cooled vertically in a casing with a cold bath of -34 ±0.5 ℃, the vacuum source is turned on and then the air flow rate is adjusted to 15L/h. For a while, the stable pressure difference of U-tube differential pressure gauge is 2KPA ±0.05KPA (see Figure 5). When the sample chooses 25 ℃, 20 ℃, 15 ℃, 10 ℃, 5 ℃, 0 ℃, -5 ℃ and-7 ℃ separately as the initial suction temperature, the cold filter point of the sample is determined by controlling the different suction times.

Table 9. Test results of the effect of suction times on cold filter point (the first group)

|

Sample temperature (℃) |

25 |

20 |

15 |

10 |

5 |

0 |

-5 |

-7 |

|

Test result (℃) |

-12 |

-12 |

-11 |

-11 |

-10 |

-10 |

-9 |

-9 |

Table 10. Test results of the effect of suction times on cold filter point (the second group)

|

Sample temperature (℃) |

25 |

30 |

15 |

10 |

5 |

0 |

-5 |

-7 |

|

Test result (℃) |

-12 |

-12 |

-11 |

-10 |

-10 |

-10 |

-9 |

-9 |

From the test results of Table 9 and Table 10, it can be seen that when the suction times are less than 15 times, the measurement results are basically unchanged. However, when the suction times are increased to a certain extent, the cold filter point measurement results will be on the low side. Similarly, when the suction times is too few, the measurement result of cold filter point is on the high side. In the process of suction, it will have a certain effect on the temperature of the oil entering the pipette. Meanwhile, with the increase of the suction times, it will have an impact on the precipitation of crystals in the oil products. So, it is necessary to reform the crystal, which will cause the cold filter point temperature to be on the low side. Therefore, in order to ensure the accuracy of the measurement results, especially for the edge oil, the cloud point is determined first, and then the suction starts at 5 ℃ before the cloud point.

- 3 The influence of other factors

When gasoline and diesel are mixed, a small amount of gasoline will also have a certain effect on diesel. For the same sample under the same conditions, the effect of 1%, 5%, 10% and 25% gasoline on the cold filter point is mixed with the prescribed cooling sample, and the test results of the two groups are shown in Table 11 and Table 12 respectively.

Table 11. The effect of gasoline content on cold filter point (the first group)

|

Gasoline content (%) |

1% |

5% |

10% |

25% |

|

Test result (℃) |

-10 |

-11 |

-13 |

-16 |

Table 12. The effect of gasoline content on cold filter point (the second group)

|

Gasoline content (%) |

1% |

5% |

10% |

25% |

|

Test result (℃) |

-10 |

-11 |

-13 |

-16 |

According to the test results of Table 11 and Table 12, when gasoline is mixed with diesel, the influence on diesel cold filtration is greater with the increase of gasoline content. Therefore, in the process of sample sampling and inspection, it is necessary to ensure the cleanliness and reliability of all kinds of appliances in order to avoid the mixed use of gasoline and diesel oil and reduce the impact on the test results of diesel cold filter point.

3. Improvement measures

3.1 Reasonable installation and adjustment of cold filter point equipment and facilities

Through a fixed filter before the test, extend the filter to the bottom of the test cup, and then adjust the 1.5mm ±0.2mm distance between the thermometer and the test cup (as shown in Figure 6). Ensure that the distance between the filter and the thermometer from the bottom of the sample cup meets the requirements of SH/T0248-2019 "determination of Cold filter Point of Diesel Oil and Civil heating Oil". Check the vacuum device of the cold filter point before the test, in order to control the pressure difference of the water level pressure difference meter at 2kPa ±0.05kPa, let the U-tube pressure difference meter be fixed in the range of 200mm H 2O ±1mm H2O.

3.2 The control of cold filter point during test operation

Under the condition that the temperature of the quality inspection room is not lower than 15 ℃, the temperature of the sample is controlled at 30 ±5 ℃. In order to measure the cold filter point more accurately, it is best to test the cloud point of the sample first. The test is carried out at the temperature above 5 ℃ of the cloud point to avoid too much or too little suction times to affect the cold filter point measurement results.

3.3 The influential control of other factors

From the beginning of sampling, the sampler and test apparatus should be strictly controlled to ensure cleanliness and dryness and put an end to the mixed use of

|

Fix the distance between the filter, thermometer and the bottom of the sample cup |

|

Filter |

|

Thermometer |

Figure 6. Adjustment diagram of thermometer and filter device

gasoline and diesel test equipment to avoid the effect of gasoline mixing on the cold filter point of diesel oil.

The choice of thermometer for diesel oil in cold filter point test is a small detail that is often ignored by experimenters. In SH/T0248-2019 "determination of cold filter point of diesel oil and civil heating oil", it is stipulated that when the temperature of cold filter point is higher than -30 ℃ (including -30 ℃), the range of GB-37 thermometer in GB/T514-2005 is -38 ℃ to 50 ℃. When the temperature of cold filter point is lower than-30 ℃, the range of GB-36 thermometer in GB/T514-2005 is -80 ℃ to 20 ℃, and the range of cold bath temperature is -80 ℃ to 20 ℃. The suitable thermometer should be selected reasonably according to the actual situation.

4. Concluding remarks

The cold filter point test of diesel oil is mainly affected by environmental factors, equipment factors and human factors. Among them, the most critical dominant factor is human factors, environmental factors and equipment factors can be corrected by the testers in the actual operation process. The tester must skillfully master the standard process of the cold filter point test operation, have a clear understanding of the key points of the operation process and the environmental and equipment factors that affect the test results, and find out the problems in the test process in time. In addition, analyzing the causes, finding ways to solve the problems and improving the sense of responsibility are the basic qualities that the testers must possess. Only in this way can we accurately get the test results of the cold filter point to improve the level of quality management.